Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Full Aluminum Case Brushless Servo Supplier: A Comprehensive Guide

In today's competitive industrial landscape, choosing the right servo system is critical for ensuring efficiency, precision, and durability. Among the many options available, the full aluminum case brushless servo stands out as a reliable choice for demanding applications. If you're looking for a supplier to meet your specific needs, understanding the technology, benefits, and factors to consider in selecting a full aluminum case brushless servo supplier is essential.

In this guide, we'll delve into what makes a brushless servo with a full aluminum case a preferred choice in various industries, the advantages it offers, and how to select the right supplier to enhance your business's performance.

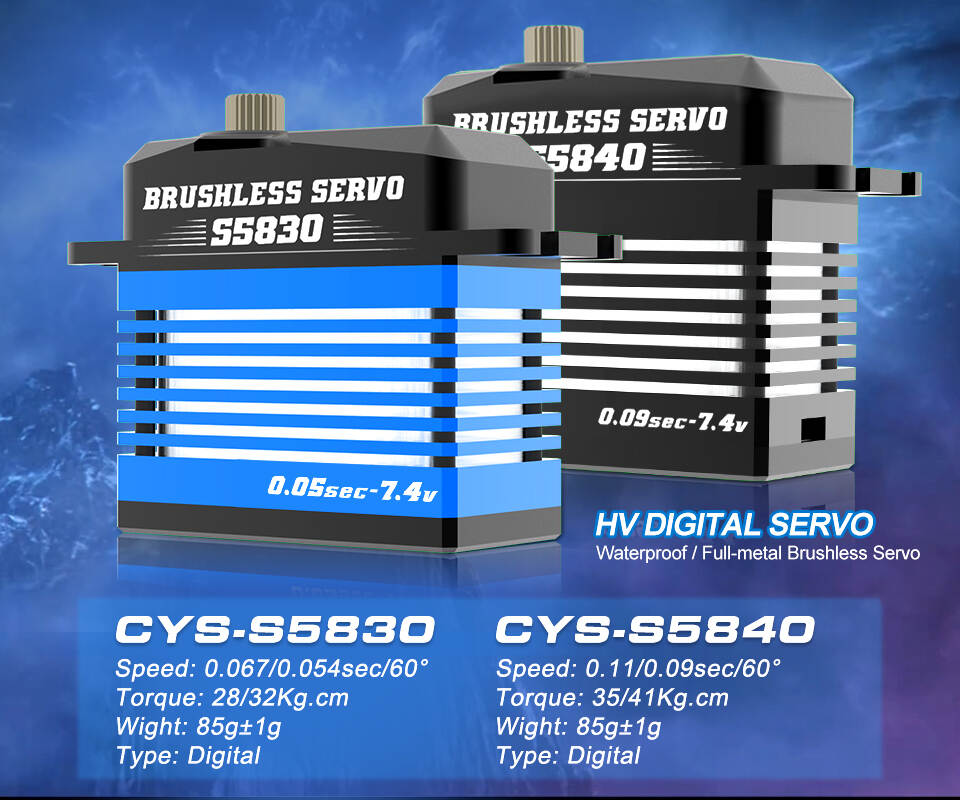

What Is a Full Aluminum Case Brushless Servo?

A brushless servo is an electric motor system designed for high-precision control of mechanical movement. Unlike traditional brushed motors, brushless servos operate without physical brushes, which significantly reduces wear and tear and increases their lifespan. The full aluminum case further enhances the performance and durability of these servos, providing a robust and efficient solution for industrial automation, robotics, aerospace, and other high-performance sectors.

Key Features of Full Aluminum Case Brushless Servos

Brushless Motor: The absence of brushes in the motor results in less friction, less heat generation, and greater efficiency, making these servos ideal for high-end applications.

Full Aluminum Casing: The aluminum case provides superior heat dissipation and protects the internal components from environmental factors such as dust, moisture, and impact.

High Precision: These servos are known for their accuracy and repeatability, ensuring that movements are executed with precision.

Durability: With fewer moving parts and a robust outer casing, these brushless servos last longer than their brushed counterparts, reducing maintenance costs and downtime.

Why Choose a Full Aluminum Case Brushless Servo?

There are several reasons why industries are opting for full aluminum case brushless servos, particularly for applications where precision and longevity are critical. Let’s explore some of the primary benefits:

1. Enhanced Durability and Heat Management

One of the standout advantages of choosing a full aluminum case brushless servo is its enhanced durability. The aluminum casing not only protects the motor from physical damage but also acts as a heat sink, ensuring that heat generated during operation is effectively dissipated. This makes the servo less likely to overheat, extending its operational lifespan.

2. High Efficiency and Performance

Brushless servos are inherently more efficient than their brushed counterparts. The lack of brushes means less friction and fewer parts that can wear down over time. A full aluminum case brushless servo operates more smoothly and reliably, offering consistent performance even in harsh conditions. This is particularly advantageous in industries like robotics and automation, where uninterrupted performance is crucial.

3. Precision Control

Precision is critical in industries such as aerospace, manufacturing, and medical devices, where even the smallest errors can lead to costly consequences. Full aluminum case brushless servos are renowned for their high precision and control capabilities, ensuring smooth, accurate, and repeatable movements. This level of control is essential in high-stakes applications where performance consistency is paramount.

4. Low Maintenance

Thanks to the brushless design, there are fewer moving parts that can wear out, which translates to lower maintenance requirements. The robust aluminum casing adds another layer of protection, ensuring that the internal components remain shielded from environmental hazards like dust, debris, or moisture. This combination of durability and low maintenance makes the full aluminum case brushless servo a cost-effective solution for businesses.

Applications of Full Aluminum Case Brushless Servos

Full aluminum case brushless servos are used across a wide range of industries due to their versatility and performance advantages. Some of the most common applications include:

1. Industrial Automation

In manufacturing and automation, precision and reliability are key. Full aluminum case brushless servos are frequently used in automated assembly lines, CNC machinery, and robotic arms, where high precision and consistent performance are required. The durability of the aluminum casing also makes these servos ideal for use in environments with high levels of vibration or physical stress.

2. Aerospace

In aerospace applications, weight and performance are critical factors. Full aluminum case brushless servos are lightweight yet durable, making them ideal for controlling the movements of aircraft components, such as flaps, ailerons, and landing gear. Their high efficiency ensures minimal power consumption, which is a crucial advantage in aviation.

3. Medical Devices

In the medical field, equipment such as robotic surgical systems and diagnostic machines rely on precise and smooth movements. Full aluminum case brushless servos provide the accuracy required in these critical environments, ensuring that medical devices operate reliably and safely.

4. Robotics

Robotics applications require high-performance motors that can operate smoothly under various load conditions. Full aluminum case brushless servos offer the precision and durability needed in robotics, making them the preferred choice for both industrial and research robots.

Factors to Consider When Choosing a Full Aluminum Case Brushless Servo Supplier

Finding the right full aluminum case brushless servo supplier is crucial for ensuring that you receive high-quality products that meet your specific needs. Below are some key factors to consider when selecting a supplier:

1. Experience and Expertise

When selecting a supplier, it’s important to look for one with extensive experience in the field of servo motors, particularly in the production of full aluminum case brushless servos. An experienced supplier will have a deeper understanding of the technology and its applications, ensuring that they can provide expert advice and support.

2. Product Quality and Certifications

Ensure that the supplier adheres to international quality standards and possesses relevant certifications, such as ISO 9001. High-quality materials and manufacturing processes are essential for producing reliable and durable full aluminum case brushless servos. Certifications also demonstrate that the supplier follows stringent quality control measures.

3. Customization Options

Different applications may require specific features or modifications to the standard servo design. A good full aluminum case brushless servo supplier should offer customization options, such as different casing materials, motor sizes, or control interfaces. Customization allows you to tailor the servo to meet your exact application requirements.

4. Customer Support and After-Sales Service

Good customer support is vital when dealing with complex equipment like brushless servos. Choose a supplier that offers comprehensive after-sales support, including technical assistance, maintenance services, and replacement parts. This ensures that any issues can be quickly resolved, minimizing downtime.

5. Competitive Pricing

While quality is paramount, pricing is also a significant consideration. A reliable supplier should offer competitive pricing without compromising on product quality. Additionally, consider suppliers that provide volume discounts for large orders, helping you reduce costs when scaling up production.

How to Evaluate a Full Aluminum Case Brushless Servo Supplier

Once you’ve narrowed down your list of potential suppliers, the next step is to evaluate their capabilities. Here are some steps to help you make the right choice:

1. Request Samples

Before committing to a large order, request product samples from the supplier. Testing the samples will give you a clear idea of the performance, build quality, and compatibility with your application. Pay attention to the materials used, the smoothness of operation, and any potential design flaws.

2. Check for Reviews and Testimonials

Look for reviews and testimonials from other businesses that have worked with the supplier. This will give you insight into the supplier’s reputation, reliability, and customer satisfaction. Positive feedback from industry peers is a good indicator of a trustworthy supplier.

3. Visit the Supplier’s Facility

If possible, arrange a visit to the supplier’s manufacturing facility. This will allow you to see their production processes firsthand and assess whether they have the capacity to meet your volume and quality requirements. A well-organized, clean, and efficient facility is a good sign of a professional operation.

4. Evaluate the Supplier’s Communication

Good communication is key to a successful partnership. Evaluate how promptly and effectively the supplier responds to inquiries. Clear and timely communication is essential, especially when dealing with complex technical specifications and large orders.

The Future of Full Aluminum Case Brushless Servos

As technology continues to evolve, the demand for high-performance brushless servos will only grow. Advancements in materials, motor design, and control systems are making these servos more efficient, precise, and durable. The use of full aluminum casings will continue to be a preferred choice due to their excellent heat dissipation and protective properties.

In the future, we can expect to see more innovation in servo technology, including the integration of IoT features for remote monitoring and control, improved energy efficiency, and smaller, more compact designs for space-constrained applications.

Conclusion

Choosing the right full aluminum case brushless servo supplier is crucial for businesses that rely on high-performance motor systems. These servos offer numerous advantages, including enhanced durability, precision, and low maintenance requirements, making them ideal for a wide range of industrial applications. When selecting a supplier, consider factors such as experience, product quality, customization options, and customer support to ensure a successful partnership.

By taking the time to thoroughly evaluate potential suppliers, you can find the right partner to meet your needs and deliver reliable, high-quality full aluminum case brushless servos that will drive your business forward.