Email cannot be empty

Password cannot be empty

checkout as a guest

or

Facebook

Google

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

Unveiling the Mysteries of Reducers: The Wise Transformers of Industrial Power

2024-08-17 16:22:12

Introduction

In the vast landscape of industrial realms, reducers stand as unsung yet indispensable heroes.

With their unique capability of decelerating and enhancing torque, they provide stable and

robust power support to a myriad of mechanical devices. Today, let us delve into the world of

reducers and explore how they have emerged as the intelligent choice for industrial power

transmission.

I. Definition and Role of Reducers

Firstly, let's clarify the definition of reducers. Serving as the bridge between motors and loads,

reducers transform the high-speed, low-torque power of motors into low-speed, high-torque

outputs through precise meshing of internal gears. This conversion process enables

mechanical equipment to operate smoothly under various working conditions, fulfilling

diverse production requirements.

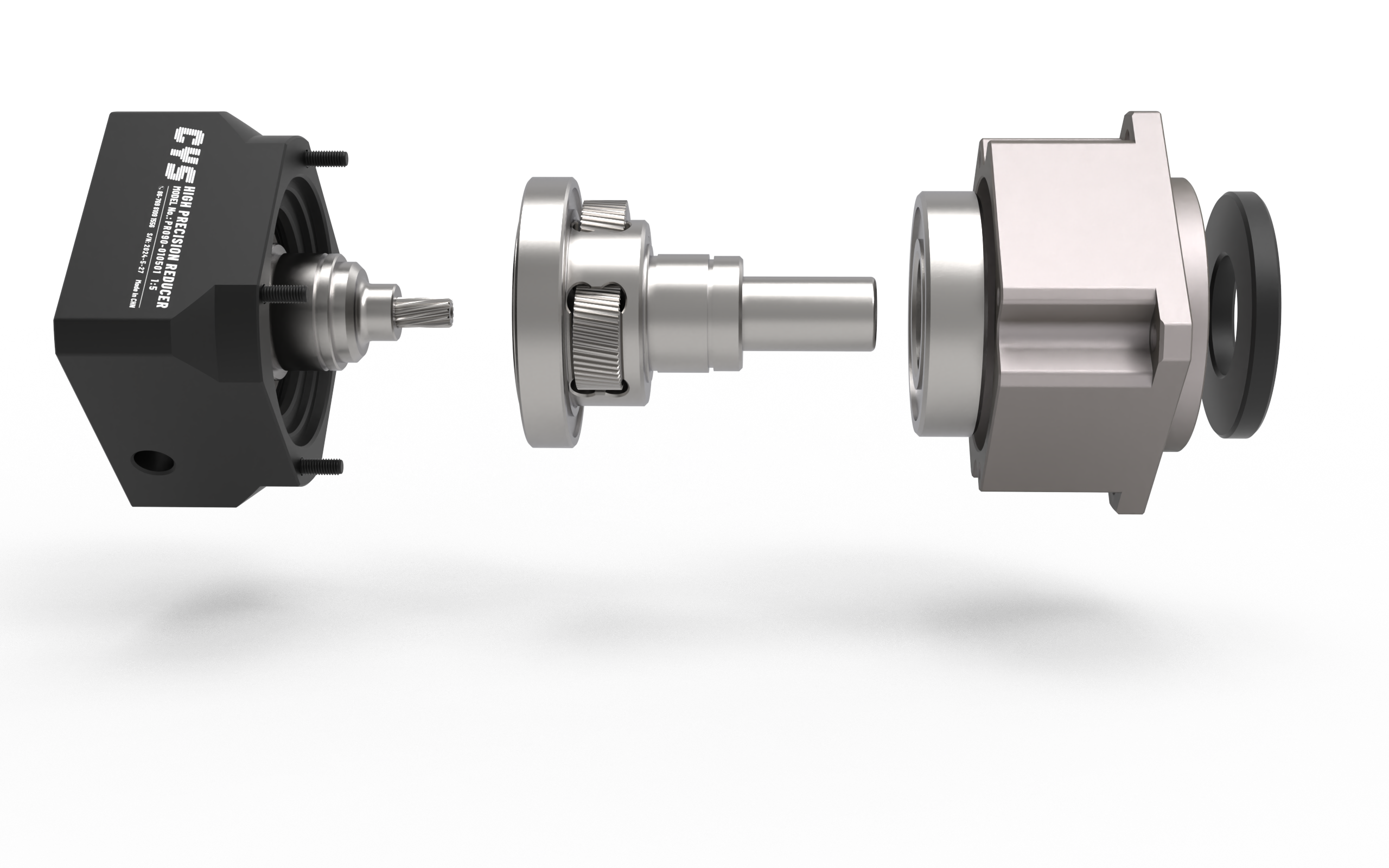

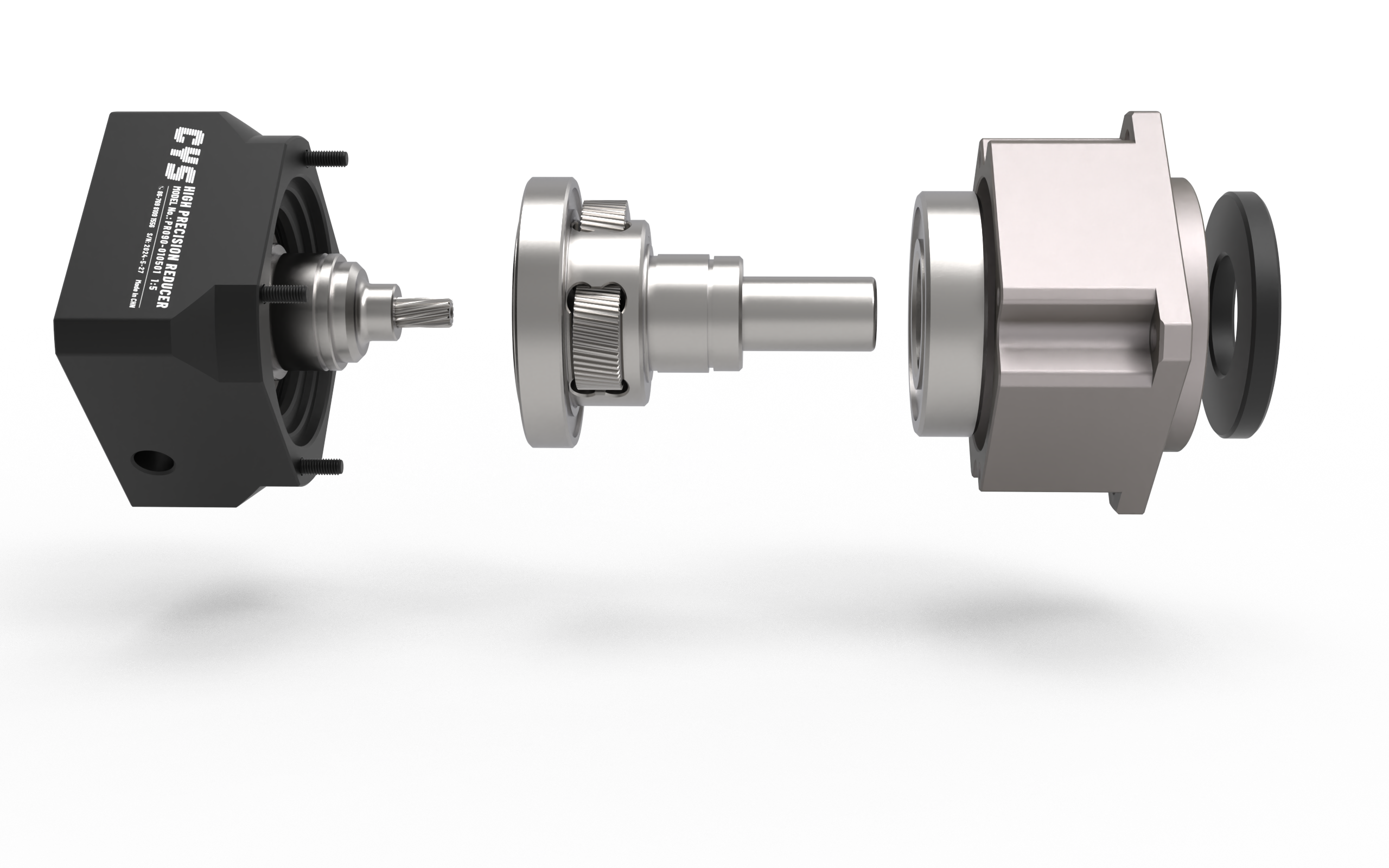

II. Working Principle of Reducers

The working principle of reducers is not intricate, yet its design is exceedingly intricate. When

a motor starts, power is transmitted through the input shaft to the reducer's gearbox. Inside

the gearbox, multiple drive gears engage with each other at specific ratios, achieving a

reduction in speed and an increase in torque. Ultimately, the converted power is transmitted

through the output shaft to the load, driving it into motion.

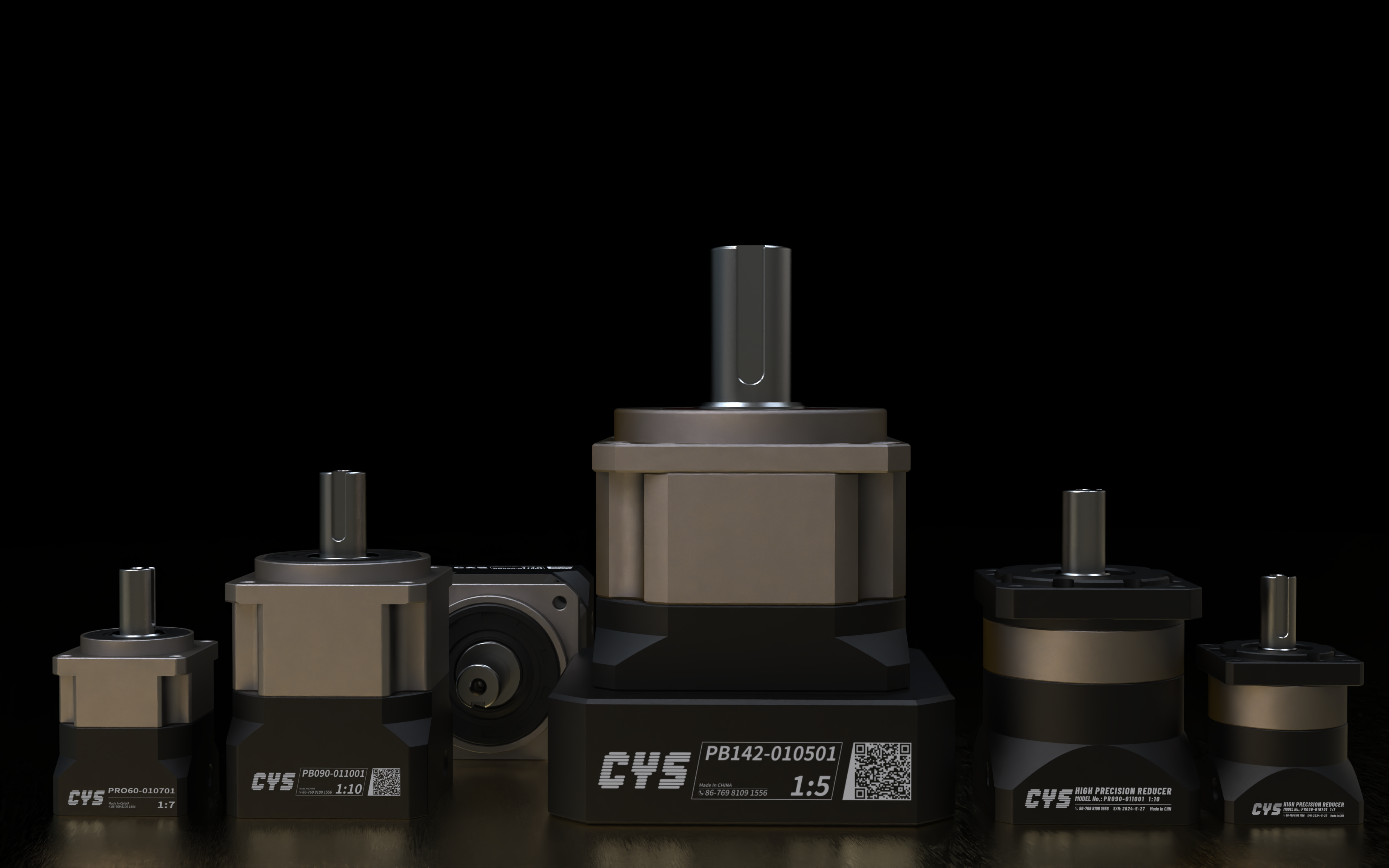

III. Application Fields of Reducers

The application scope of reducers is exceptionally broad, encompassing virtually all industrial

sectors that require power transmission. From heavyweight machinery such as metallurgical

equipment and mining machinery, to precision devices like automation equipment and robotic

arms, and even everyday essentials like elevators and automatic doors, reducers play a pivotal

role.

IV. Advantages and Characteristics of Reducers

Efficient Transmission: Optimized gearbox structures minimize energy loss during power

transmission, enhancing transmission efficiency.

Strong Load-bearing Capacity: By boosting torque, reducers enable equipment to withstand

greater loads, prolonging service life.

Compact Design: A compact design makes reducers small in size and light in weight,

facilitating installation and maintenance.

Smooth Operation: High-precision gear meshing ensures smooth reducer operation, reducing

vibration and noise.

V. Selection and Maintenance of Reducers

Proper selection is the prerequisite for ensuring efficient reducer operation. When choosing

reducers, factors such as motor speed, load characteristics, and working environment must be

considered. Additionally, regular maintenance is indispensable, including checking gear wear,

replacing lubricants, and adjusting transmission clearances, to ensure long-term stable

reducer operation.

VI. Market Trends and Future Developments

As industrial technology advances, the reducer industry continues to innovate and evolve.

In the future, reducers will prioritize energy efficiency, intelligence, and modular design.

Furthermore, with the rapid development of new energy and smart manufacturing sectors,

the reducer market is poised to embrace even broader development prospects.

Conclusion

As a crucial component in industrial power transmission, the importance of reducers cannot

be overstated. By gaining a profound understanding of their definitions, working principles,

application fields, advantages, and market trends, we can better appreciate these heroes

behind the scenes in the industrial world. In the years to come, we have every reason to

believe that reducers will continue to play their unique roles, contributing even more

significantly to the advancement of industrial domains.

.

In the vast landscape of industrial realms, reducers stand as unsung yet indispensable heroes.

With their unique capability of decelerating and enhancing torque, they provide stable and

robust power support to a myriad of mechanical devices. Today, let us delve into the world of

reducers and explore how they have emerged as the intelligent choice for industrial power

transmission.

I. Definition and Role of Reducers

Firstly, let's clarify the definition of reducers. Serving as the bridge between motors and loads,

reducers transform the high-speed, low-torque power of motors into low-speed, high-torque

outputs through precise meshing of internal gears. This conversion process enables

mechanical equipment to operate smoothly under various working conditions, fulfilling

diverse production requirements.

II. Working Principle of Reducers

The working principle of reducers is not intricate, yet its design is exceedingly intricate. When

a motor starts, power is transmitted through the input shaft to the reducer's gearbox. Inside

the gearbox, multiple drive gears engage with each other at specific ratios, achieving a

reduction in speed and an increase in torque. Ultimately, the converted power is transmitted

through the output shaft to the load, driving it into motion.

III. Application Fields of Reducers

The application scope of reducers is exceptionally broad, encompassing virtually all industrial

sectors that require power transmission. From heavyweight machinery such as metallurgical

equipment and mining machinery, to precision devices like automation equipment and robotic

arms, and even everyday essentials like elevators and automatic doors, reducers play a pivotal

role.

IV. Advantages and Characteristics of Reducers

Efficient Transmission: Optimized gearbox structures minimize energy loss during power

transmission, enhancing transmission efficiency.

Strong Load-bearing Capacity: By boosting torque, reducers enable equipment to withstand

greater loads, prolonging service life.

Compact Design: A compact design makes reducers small in size and light in weight,

facilitating installation and maintenance.

Smooth Operation: High-precision gear meshing ensures smooth reducer operation, reducing

vibration and noise.

V. Selection and Maintenance of Reducers

Proper selection is the prerequisite for ensuring efficient reducer operation. When choosing

reducers, factors such as motor speed, load characteristics, and working environment must be

considered. Additionally, regular maintenance is indispensable, including checking gear wear,

replacing lubricants, and adjusting transmission clearances, to ensure long-term stable

reducer operation.

VI. Market Trends and Future Developments

As industrial technology advances, the reducer industry continues to innovate and evolve.

In the future, reducers will prioritize energy efficiency, intelligence, and modular design.

Furthermore, with the rapid development of new energy and smart manufacturing sectors,

the reducer market is poised to embrace even broader development prospects.

Conclusion

As a crucial component in industrial power transmission, the importance of reducers cannot

be overstated. By gaining a profound understanding of their definitions, working principles,

application fields, advantages, and market trends, we can better appreciate these heroes

behind the scenes in the industrial world. In the years to come, we have every reason to

believe that reducers will continue to play their unique roles, contributing even more

significantly to the advancement of industrial domains.

.

Contact us